Bosco has been awarded the design and realization of the main control room that will manage the largest industrial gas complex in the world to supply 75,000 tonnes per day (20,000 of oxygen and 55,000 of nitrogen) to Saudi Aramco refinery and combined cycle integrated gasification under construction in Jazan, Saudi Arabia.

The plant uses proven gasification technologies that take lower-value raw materials and convert them, through a low-emission process, into synthesis gas which is then used to make higher-value products. The complex serves Aramco's Jazan refinery, a megaproject to process 400,000 barrels per day of crude oil to produce ultralight sulfur diesel, gasoline and other products.

The Jazan gas plant is not only a critical infrastructure for energy production in Saudi Arabia, but also a symbol of a cleaner and more sustainable energy future.

Central Control Room of Jazan Gas Plant: Designed and Built

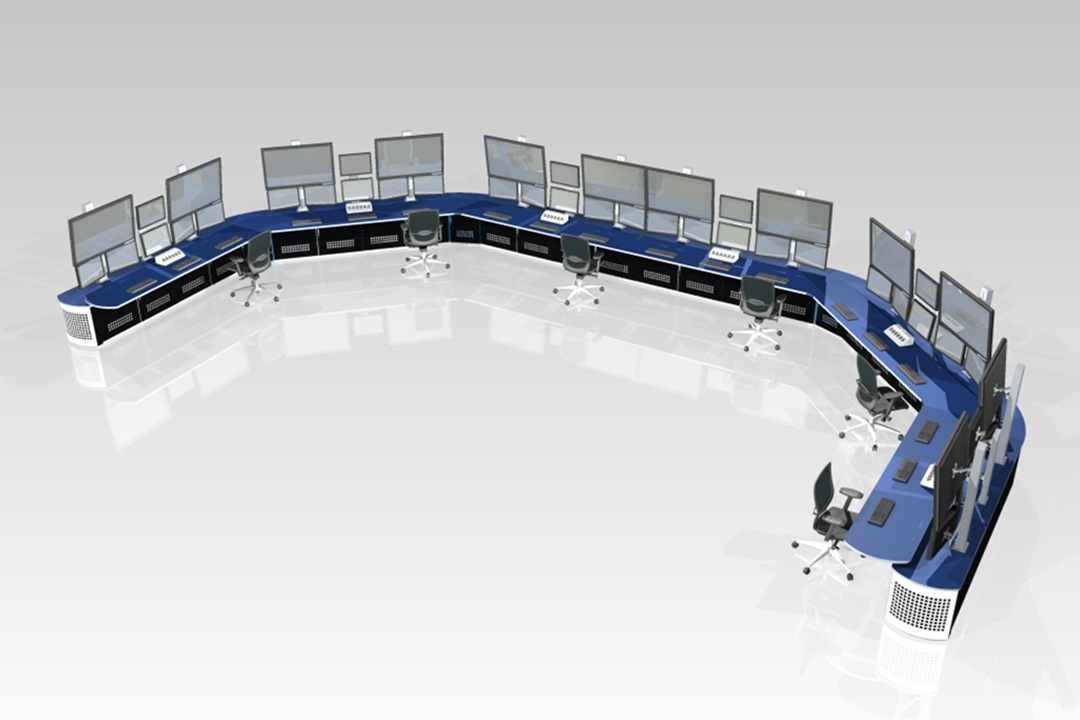

What is striking about the central control room of the Jazan gas plant is the large 3000 series control console positioned in the center of the room in a bay layout. Made up of several independent modules to facilitate assembly and future expansions, this spectacular control station is entirely motorized and equipped with a sit-stand system, with the possibility of raising the work surfaces of each module both independently and simultaneously.

The double top allows the many displays to be housed on the rear surface, keeping the work surface freer and aesthetically more pleasing. The cabinets under the work surface are designed to accommodate electronic equipment and to ergonomically organize cables.