The Italian oil & gas automation giant Sensia has awarded Bosco a contract for the setup of the central control room of a floating production and storage unit, called P-79, for the development of the Búzios offshore field in Brazil.

The platform will have a processing capacity of 180,000 barrels of oil and 7.2 million cubic meters of gas per day. This is an FPSO (Floating Production Storage and Offloading) type unit, which produces, stores and transfers oil.

The Búzios field, discovered in 2010, is the largest underwater oil field in the world. It is expected to surpass a daily production of 2 million barrels of equivalent oil by the end of the decade, becoming Petrobras highest-producing asset.

Located in the Santos basin, the P79 plays a crucial role in Brazil's energy supply, and its beating heart is undoubtedly the central control room.

The control consoles for the control center of a floating platform such as Petrobras P-79 must meet more stringent requirements than other application sectors.

Our control consoles, in addition to being suitable for the most critical environments guaranteeing 24h/7d operation, are suitable for naval industrial installation and have the inclination and vibration requirements of the current regulations.

Petrobas also requested modular and flexible technical furniture for future expansions and for ease of assembly, with consoles made up of a series of independent modules.

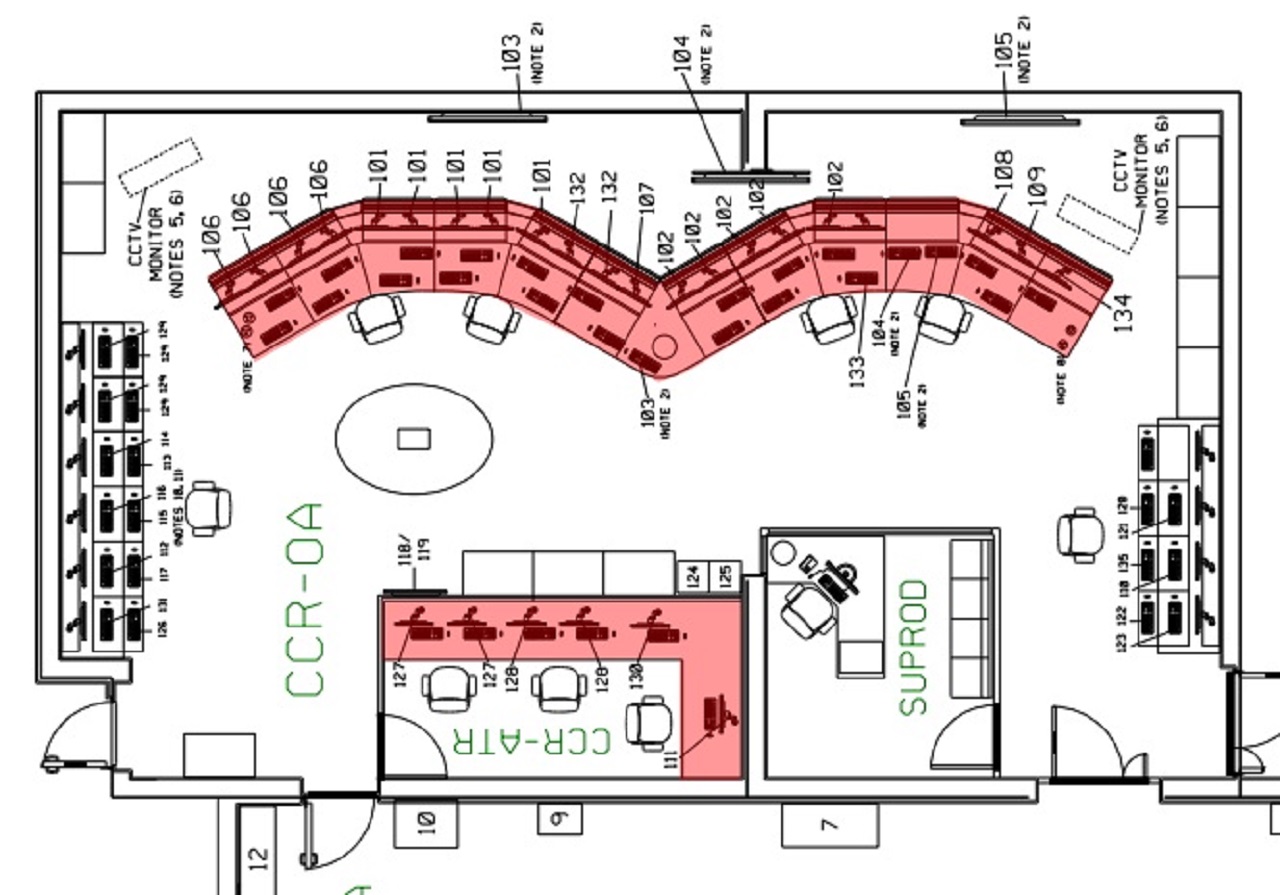

The central control room of the P79 is ergonomically organized into different work areas. The design of the room takes into account the diversification of tasks and, at the same time, the frequency and type of contacts between operators, as well as the degree of importance and frequency of use of the control and information panels.

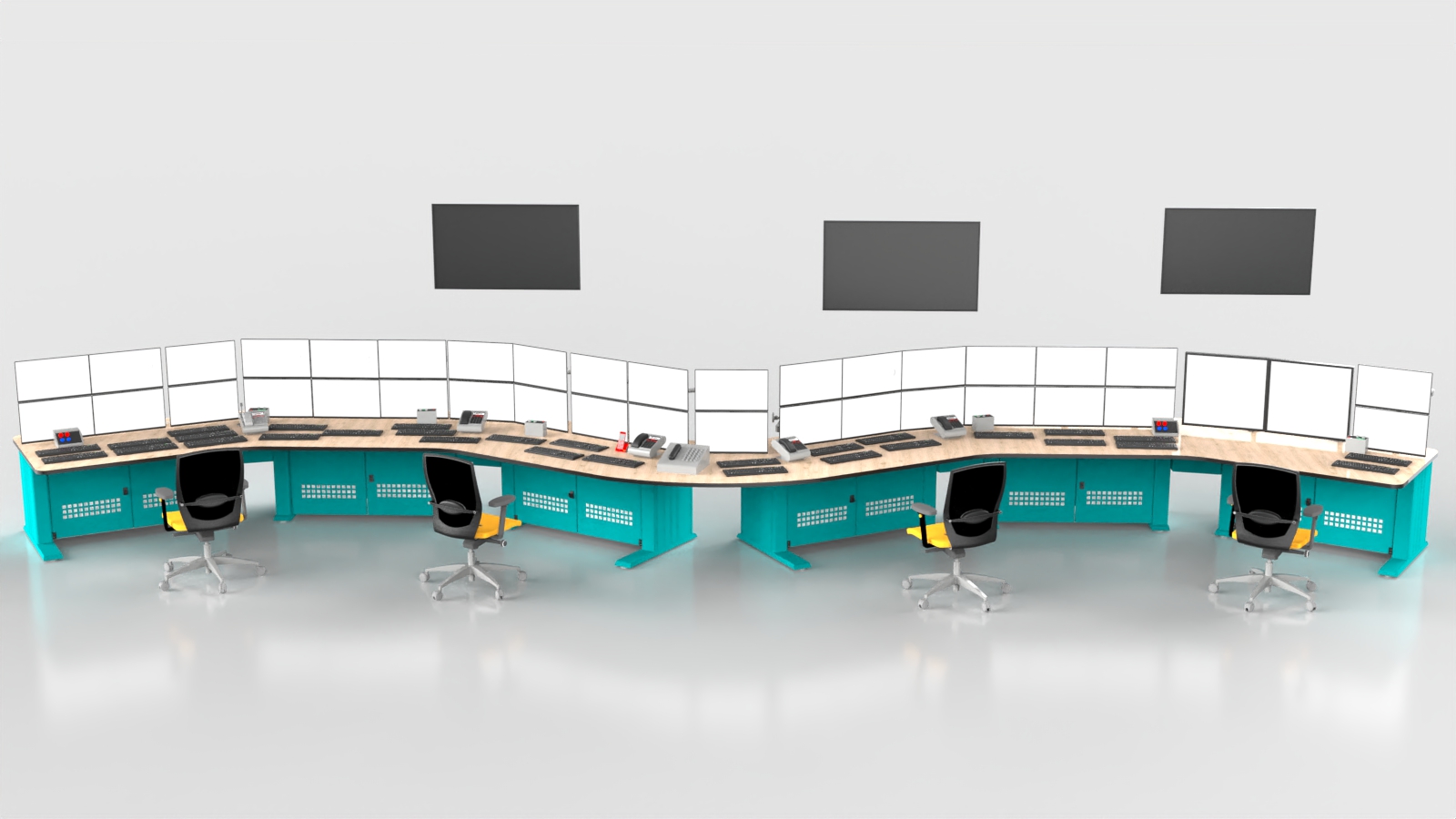

What is most striking about the Petrobras control center is the large central control console 2500XL series, which accommodates 4 operators. This technical desk with a great visual impact is equipped with cabinets under the work surface for housing equipment and ergonomically organizing cable flows. The double top allows the many monitors to be housed on the lower level, keeping the work surface freer.

With a gull-wing layout, this control station facilitates consultation of the displays and information/control panels by the individual operator, as well as teamwork and the exchange of information.

In addition to the central console, we provided control desks for a total of 18 operators and a meeting table for on-site consultation.